Research: Nanomaterials in 3D printing

1) Concomitant 3D Printing of Nanoporous Metal and Polymer Architectures

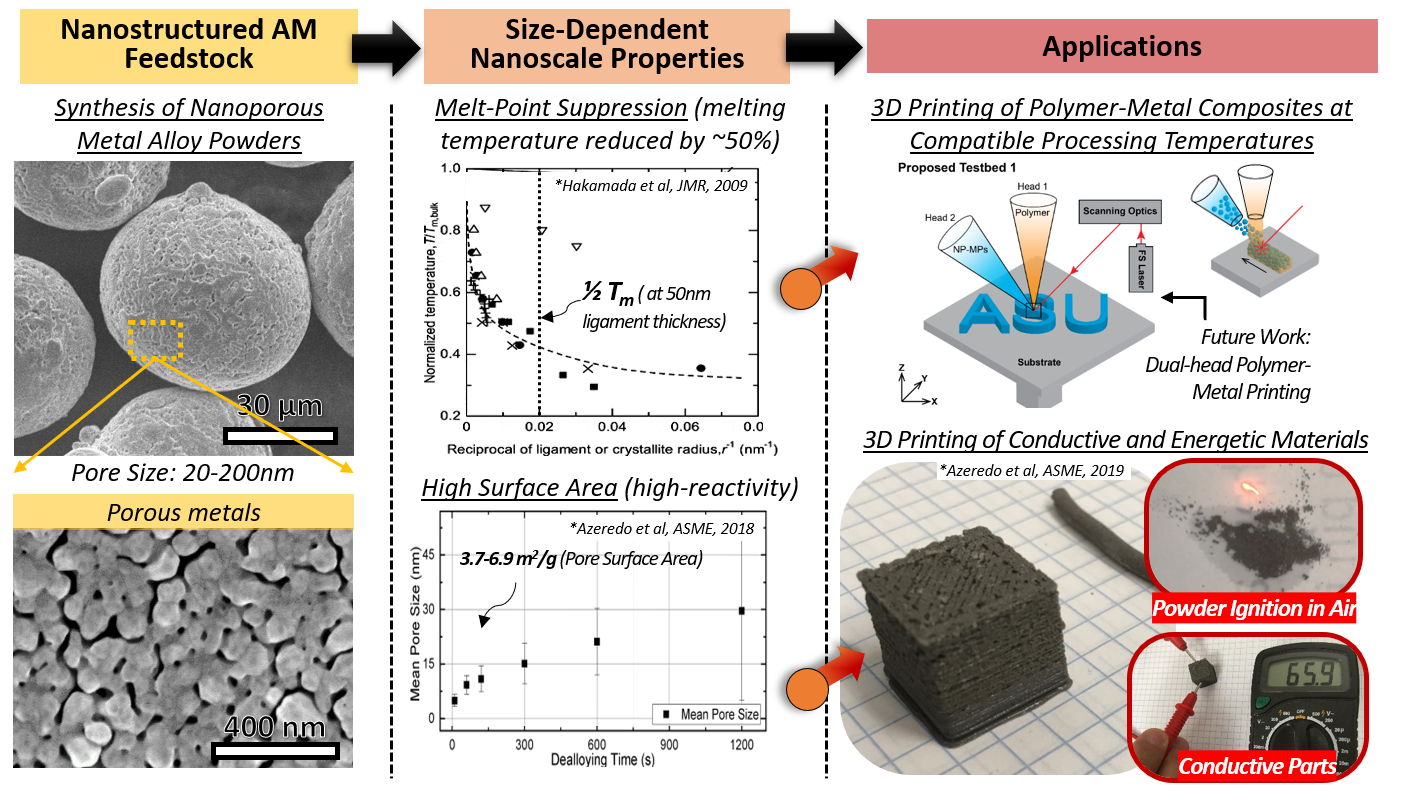

Application. Multi-material printing has been a highly desirable capability in the additive manufacturing community because it can enable heterogeneous materials to be integrated into complex architectures with added multi-functionallity. The world is full of heterogeneous materials joined in a variety of ways to combine the properties of polymers, metals and ceramics into functional products everyday. So, why don’t we see 3D printing strategies that can 3D print polymers, ceramics and metals concomitantly (hint: “manufacturing challenges”)?

Our group is particularly interested in nanoporous metals for it has high-surface area and catalytic performance relevant to 3D print (i) energetic materials for military applications, and (ii) energy storage & harvesting devices (e.g. fast-discharging batteries and nanostructured photoanodes for hydrogen production).

Manufacturing Challenges. Today, metal 3D printing is accomplished by using a combination of (i) powder or filament deposition methods (e.g. spray coating) to add material, and (ii) directed heat sources (e.g. a high-energy point laser source) that focuses enough power density to sinter, melt and weld high-temperature metal feedstock. The high-melting temperature of most metals (i.e. > 900 ºC) has deemed impossible for polymers to be simultaneously printed with metals because the former vaporizes and sublimes at such temperatures. As a result, one can only print metals and polymers separately which limits our ability to fabricate complete polymer-metal architectures in a single platform with reduced need for assembly and post-processing steps.

Innovation. While solid powders have been extensively used as feedstock for metal additive manufacturing (e.g. selective laser sintering and melting), our approach proposes to use of nanostructured powder and to exploit its nanoscale properties such as size-dependent melt-point suppression. This property can reduce by 50% the processing temperature required for metal AM parts and increase its combability with thermoplastics for simultaneous printing of polymers and metals.

Key Related Publications:

- Niauzorau, S., Kublik, N., Sharstniou, A., Sampath, V., Bandarenka, H., Azeredo, B., “Electroless Dealloying Of Thin-Film Nanocrystalline Au-Ag Alloys: Mechanisms Of Ligament Nucleation And Sources Of Its Synthesis Variability”, ACS Applied Materials & Interfaces, 14, 15, 17927-17939, 2

- Ramesh, R., Niauzorau, S., Sampath, V., Wang, L., and Azeredo, B., “In-situ Temperature Dependent Optical Characterization of Nanoporous Gold Absorbers Fabricated by Thin-Film Dealloying”, Advanced Optical Materials, 2102479, 2022

- Sampath, V., Silori, P., Paradkar, P., Niauzorau, S., Sharstniou, A., Hasib, A., Villalobos, S., and Azeredo, B., “3D Printing Of Stainless Steel 316L and Its Weldability For Corrosive Environments”, Materials Science and Engineering: A, Vol. 833 (142439), 2022

- Hasib, A., Niauzorau, S., Xu, W., Kublik, N., Song, K., Azeredo, B., “Rheology scaling of spherical metal powders dispersed in thermoplastics and its correlation to the extrudability of filaments for 3D printing”, Additive Manufacturing, Vol. 41, 2021

- Niauzorau, S., Ferreira, P., Azeredo, B., “Synthesis of Porous Noble Metal Films With Tunable Porosity by Timed Dealloying”, ASME 2018 13th International Manufacturing Science and Engineering Conference, Paper No. MSEC2018-6665, College Station, TX, 2018

- Azeredo, B., Yeratapally, S. R., Kacher, J. P., Ferreira, P., Sangid, M. D., “An experimental and computational study of size-dependent contact-angle of dewetted metal nanodroplets below its melting temperature”, Applied Physics Letters, Vol. 109, Issue 21, 2016